Today we will continue to learn about the precautions of conformal coating process.

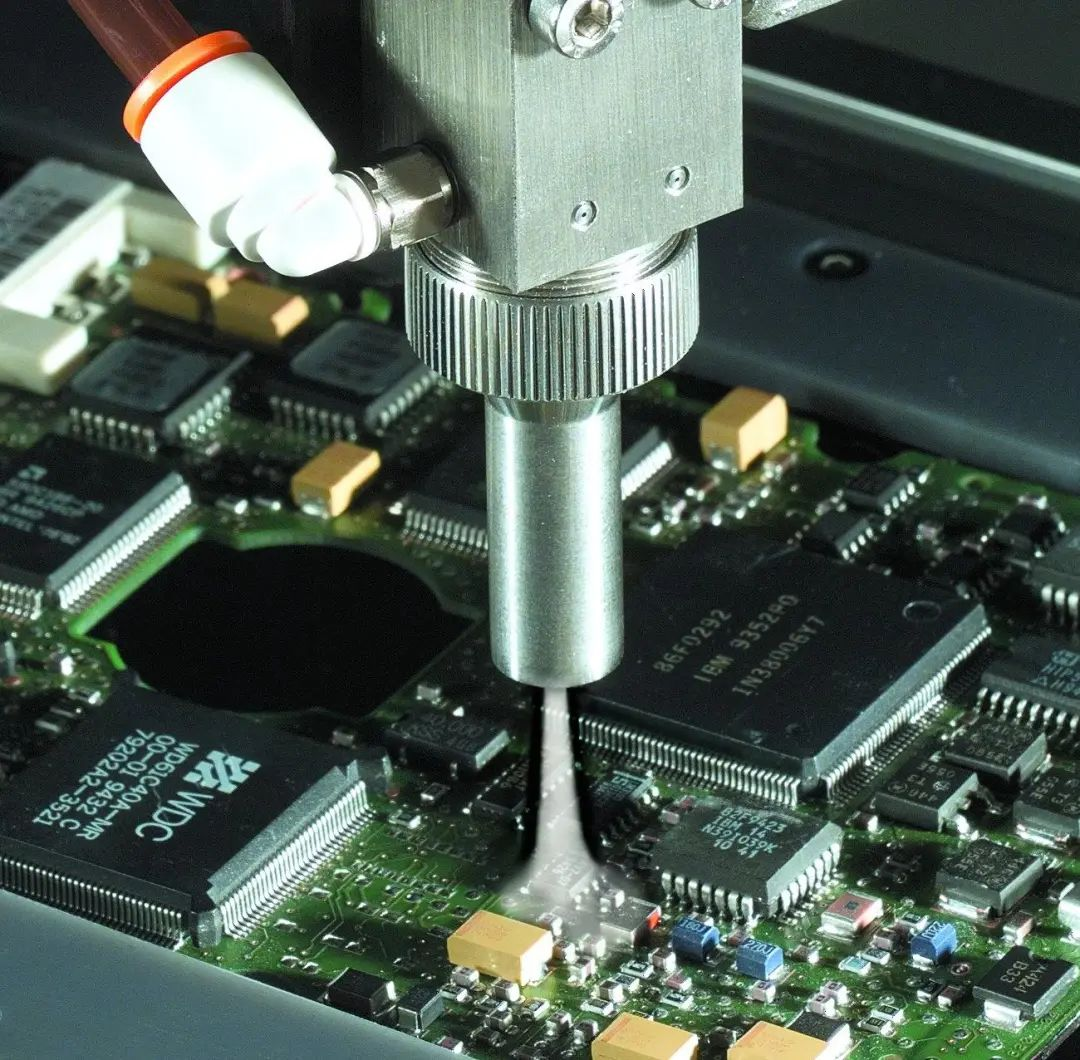

In the context of PCB manufacturing, the conformal coating spray process requires attention to the following details:

1. Process Edge Requirement:

The PCBA must have a process edge with a width of not less than 5mm to facilitate smooth machine operation along the track.

2. Size Limitations:

The dimensions of the PCBA have maximum and minimum limits, with a maximum of 410mm×410mm and a minimum of 10mm×10mm, to accommodate different production and application needs.

3. Component Height Limit:

The height of components mounted on the PCBA must not exceed 80mm to ensure uniformity and coverage during the spraying process.

4. Spray Area Separation:

The minimum distance between the spray area and the non-spray area on the PCBA should be 3mm to prevent conformal coating from contaminating areas that do not require spraying.

5. Cleaning and Baking:

Thorough cleaning of the PCBA ensures that corrosive residues are completely removed, allowing conformal coating to adhere well to the surface of the circuit board. The recommended film thickness is 0.1-0.3mm, and the baking conditions are 60°C for 10-20 minutes.

6. Components Not to be Sprayed:

During the spraying process, some components are not allowed to be sprayed, such as high-power components with heat-dissipating surfaces, power resistors, power diodes, cement resistors, dip switches, variable resistors, buzzers, battery holders, fuse holders (tubes), IC sockets, and tactile switches, which may be sensitive to heat or require heat dissipation and are not suitable for conformal coating.